|

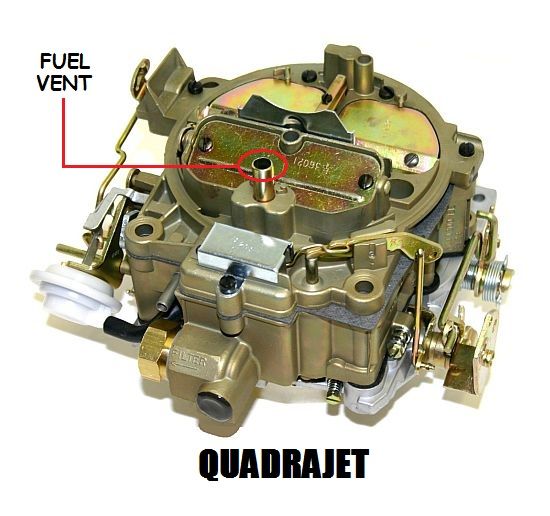

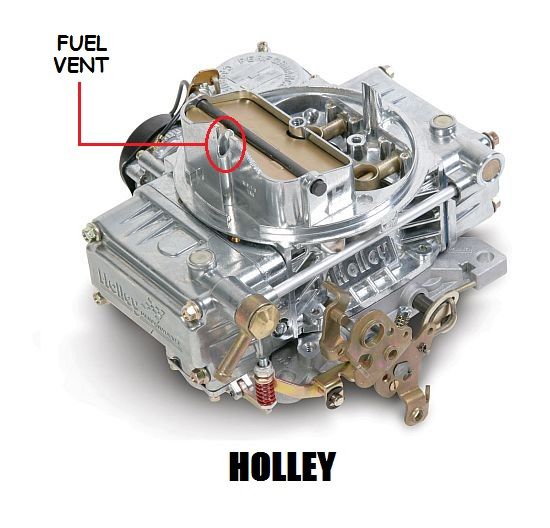

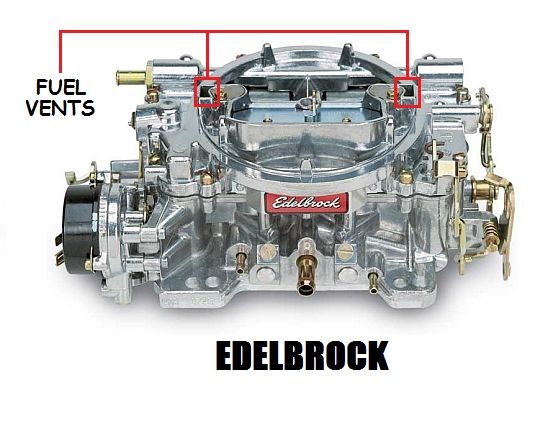

Start Your Engine! How to Get A New Engine to Fire On The First Crank.When you start your engine for the first time whether it's a new engine or a rebuild is the most important starting of that engine in it's life. It will have a lot of affect on the life of the engine, especially the cam. You need to get the engine running immediately and get that oil pressure up. Unless you get the engine running with the least amount of cranking, you can permanently scar the cam, crank, bearings, etc. So, how do I get the engine ready so it will start right off? I'm glad you asked... First. You will want to to make sure you prime your oil system right before you start your engine. This is one of the biggest savers of engines if your engine is capable of doing it. A few oil pumps operate differently, and doing it is not practical. Most engine oil pumps however can be operated with a tool or old modified distributor. You can usually buy the tool for cheap at auto parts stores, catalogs, etc. You can also modify an old distributor that fits your engine. Grind the teeth off the gear or remove it and remove the stuff on the top leaving the shaft sticking out enough to get a drill on. Use a big drill, preferably half inch. You don't have to spin it fast. You have to spin it in the same direction the distributor spins. Do it until you see oil pressure on the gauge. If you don't have a gauge, pull the rocker cover(s) and spin the pump till you see it come out by the rockers. Some people will spin the drill some, turn the engine over 90 degrees by hand, spin some more, turn the engine again, spin, turn, etc. until the engine has turned over twice. Second. Make sure the #1 cylinder is on the compression stroke. You can either put a finger over the spark plug hole while you rotate the engine by hand, or if you have the valve covers off, watch the rocker arms. If you have your finger over the hole, you will be feeling for pressure pushing your finger up when you're turning the engine over. This is the compression stroke. If you're looking at the rocker arms, when the intake rocker goes down and both rockers are closed as you're turning the engine, you're on the compression stroke. Now as the piston is coming up to TDC on the compression stroke stop rotating the engine when the timing marks line up to the timing you are going to run. You do have a new harmonic balancer don't you? If you are re-using an old balancer make sure the outer ring hasn't slipped. This can happen on old, high mileage balancers. The rubber isolator ring can crack and let the outer ring move. So, your timing will be off if you go by those marks. Not only does it cause a problem, it can be dangerous if it comes apart. So, make sure you have a good balancer. Now your engine is set. Don't turn it any more until you are ready to start it. Third. Now you can put your distributor in with the rotor pointing to the #1 terminal on the cap. You may have to back the rotor up just a bit as you drop it in as the rotor will turn just a bit as it drops into place. How do I tell when it is pointing to the #1 terminal on the cap? Before you put it in, set the cap on the distributor and put a mark on the base of the distributor right under the # 1 terminal of the cap. Now just install the distributor without the cap and line up the metal part of the rotor to the mark you just made. Now put the cap on and hook up the plug wires to the sparkplugs except for the #1 plug wire. Fourth. Now put a sparkplug into the end of the #1 plug wire and ground it to the engine. I usually set the base of the plug on a bare bolt or bare exhaust manifold. You want it away from any gas fumes and where you can see it easily. Now turn the ignition on, either with the key, or simply making sure you have a positive wire to the + terminal of the coil. Ok, now slowly turn the distributor back and forth until you see a spark from the sparkplug. As soon as it sparks, stop! Your timing is now very close to what it should be. It should let your engine start right up. You can put a timing light on it later to fine tune it after the engine is running and the cam is broken in... Now, tighten down the distributor and don't mess with it till you are ready to start your engine. Fifth. Now that your ignition timing is taken care of, we need to make sure your fuel is ready... Carburetors If you have a carburetor, you need to make sure the bowls are full. Just pouring some fuel down the throat of the carb isn't just dangerous, it can also wash down a cylinder of the engine and scar it. So don't do it. If you have a manual fuel pump, then you will have to prime the carb yourself. All you have to do is pour some gas (about 1/4 cup) down the vent tubes on the top of the carb. I usually use an eyedropper. This will fill the fuel bowls enough to run the engine long enough so the fuel pump can get the fuel from the tank to the carb. The vent tubes vary on different brands of carbs:

If you have an electric fuel pump, then all you have to do is turn it on and wait for it to pump fuel up to the carb. Fuel Injection To prime a fuel injection system, turn the ignition key to the on position and leave it on for 3-4 seconds. Now turn it off and wait for a couple seconds. Now repeat this 3-4 times. The electric fuel pump will run for 2 to 3 seconds each time. Doing this 3 to 4 times should be enough to bring the system up to pressure. Now you're ready to start your engine! Don't forget to have a fire extinquisher handy... Do it outside if you can. Bring your rpm's up right away to the directions on breaking in your new cam (usually about 2000-2500 rpm's). (Break-in isn't necessary on roller cams.) Good Luck!

Return from Start Your Engine to Hot Rod Engines

|